EXCLUSIVE DISTRIBUTORSHIP

DRILL SHAFT REBAR

CENTRALIZER SYSTEM

Durable centering devices that accurately position rebar reinforcement within drilled shafts and other foundation applications, helping ensure your next project safely maintains specified clearance requirements.

Searching for expert advice about sizing specifications or pricing before starting your project? Request a quote now to speak with our professional team today.

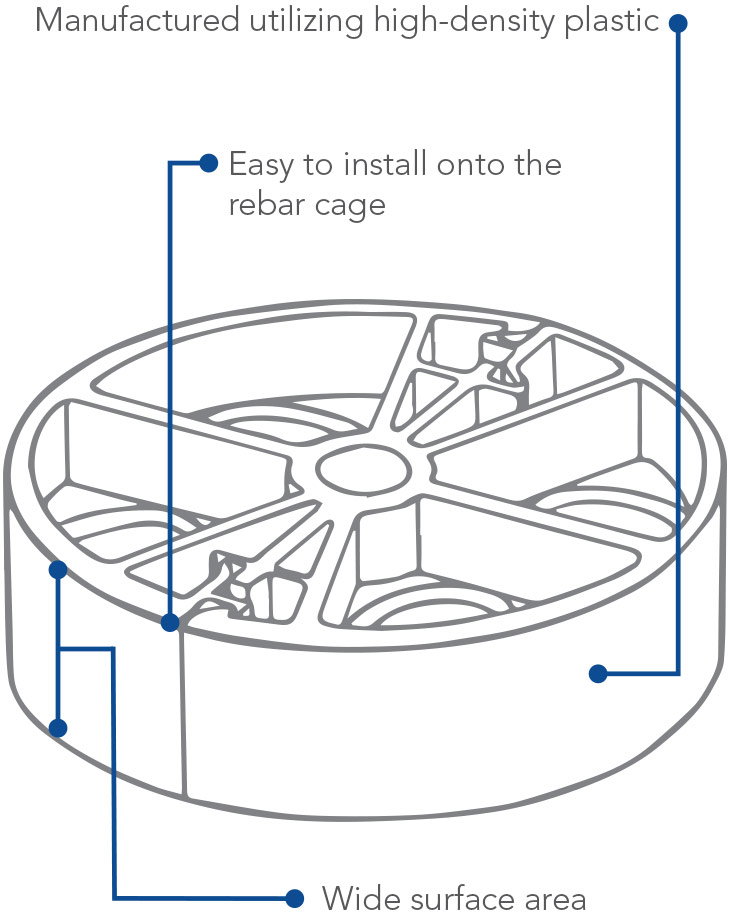

ShaftSpacer® is a plastic spacer wheel guide and alignment system for lateral positioning and centralization of rebar reinforcement cages within caissons, drilled shafts and other geotechnical construction applications. Positioning rebar within specified clearances is critical. Our line of Shaftspacer® rebar spacer wheels ensure appropriate spacing requirements are met and rebar is centralized during the installation of the pile cage and throughout concrete placement.

WHY USE IT?

In order to ensure fabricated rebar cages are properly positioned for concrete placement every time. The ShaftSpacer aligns and centers rebar cages within the drilled shaft — providing proper clearance between the rebar cage reinforcement and the interior side walls of the shaft or casing.

APPLICATIONS

CONSTRUCTION BENEFIT

ADVANTAGES

| MODEL | COVER | DIAMETER | BAR SIZE | PACKAGEING | WEIGHT |

| SS303 | 1.5" | 3" | #3 - #6 | 50 | 7 lbs |

| SS505 | 2.5" | 5" | #3 - #6 | 50 | 16 lbs |

| SS406 | 3.0" | 6" | #3 - #6 | 50 | 22 lbs |

| SS808 | 4.0" | 8" | #3 - #7 | 25 | 20 lbs |

| SS612 | 6.0" | 10.75" | #3 - #7 | 24 | 27 lbs* |

| * When shipping UPS, use dimensional wt. of 43 lbs. | |||||

SHAFTSPACER MINIMUMS

PLACEMENT RECOMMENDATIONS

READY TO GET STARTED ON YOUR NEXT PROJECT?

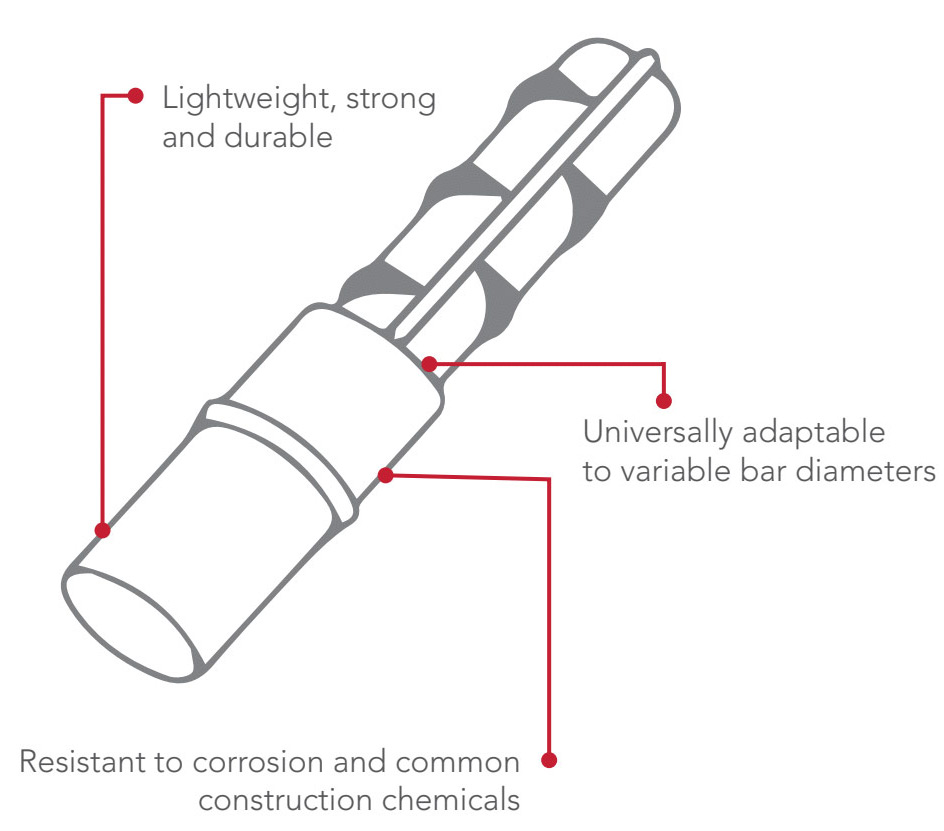

BARBOOT® is a simple and economical means of supporting and spacing rebar reinforcement vertically at the base of drilled shafts. BARBOOT® plastic rebar supports stabilize the entire rebar cage vertically within the drilled shaft and provide proper clearance between the reinforcement cage and the earthen surface. An additional advantage of rebar reinforcement boots is that the encapsulation of the ends of the vertical rebar provides added corrosion protection.

BARBOOT® rebar supports provide quality assurance for the contractor of the subcontractor’s performance. At the same time, it provides quality assurance for the engineer and owner of the contractor’s performance.

WHY USE IT?

In order to support the entire rebar cage vertically within the drilled shaft and provide proper clearance between the rebar reinforcement and the earthen surface at the bottom of the shaft. The encapsulation of the ends of the vertical rebar provides added corrosion protection.

APPLICATIONS

CONSTRUCTION BENEFIT

ADVANTAGES

| MODEL | COVER | BAR SIZE | PACKAGEING | WEIGHT | |

| BB711 | 3.0" | #5 - #14 | 50 | 29 lbs | |

| BB711FED* | 3.0" | #5 - #14 | 50 | 29 lbs | |

| BB711-6 | 6.0" | #5 - #14 | 25 | 24 lbs | |

| * Product designed specifically for FHWA & DOT projects | |||||

SHAFTSPACER MINIMUMS

PLACEMENT RECOMMENDATIONS

EXCLUSIVE DISTRIBUTORSHIP

Thank you for your submission. We will be in touch shortly!

Thank you for your submission. We will be in touch shortly!